Wear, scratch and corrosion resistant PVD colored stainless steel

Our PVD coating is an innovation in the creation of coloured stainless steel making its surface ten times harder and more durable in the process.

This is created through the process of PVD (Physical Vapor Deposition) Titanium Ion Plating which improves the performance of stainless steel by increasing wear, scratch and corrosion resistance. This makes its durability far superior to conventional coating methods such as electroplating or powder-coating.

Environmentally friendly

The PVD process is also more environmentally friendly than processes such as electroplating and painting, with zero discharge of gas, water waste or other residue.

Supplying products or recoloring your own selected products

Via our manufacturing partners we can supply proprietory fittings or take customer’s own stainless steel fittings to color via the PVD process the color of your choice. We also work with suppliers and manufacturers in enhancing existing product ranges with additional color selections.

Sheet material, long profiles and small components

We supply sheet material, long profiles and trims suitable for furniture, panels, doors and architraves for interior and exterior use.

Double Stone Steel PVD colored stainless steel can be V-Grooved and folded after coloring.

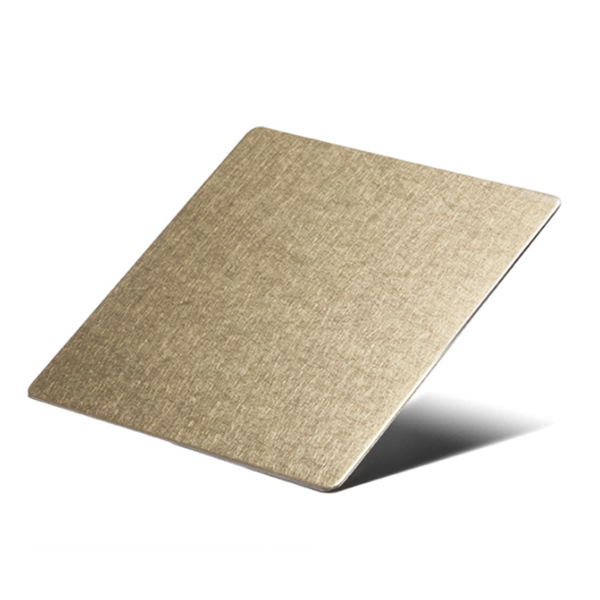

Almond Gold - Brush

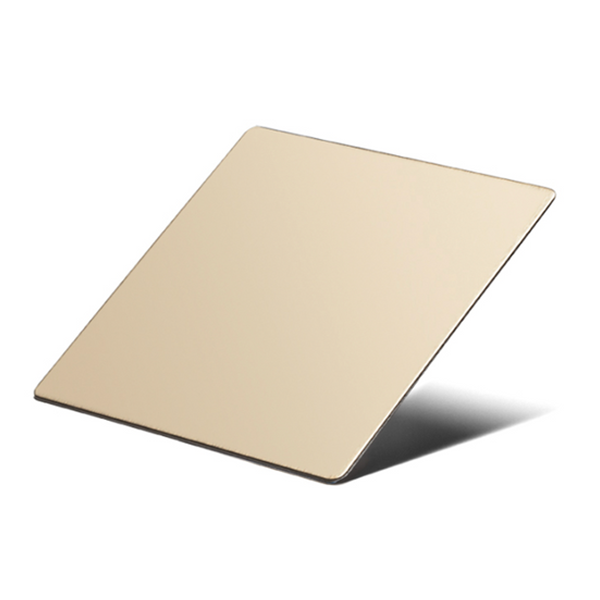

Almond Gold - Mirror

Almond Gold - Hairline

Almond Gold - Sandblasted

Almond Gold - Vibration

Wear, scratch and corrosion resistant PVD colored stainless steel.

Standard PVD coating thickness is 0.35 microns,surface flatness at the junction of two PVD coatings,creates a metal-to-metal lubricant,recoatable after coating.

The suitability of PVD for internal or external use will vary across the color ranges.

Architecture, building grids, bathroom and toilet equipment, curtain walls, gates, signs, furniture, small hardware parts, elevators, etc.